Aquarius Ultrasonic Tank-to-Tank Precision Cleaning System

Discover Aquarius™, the ultimate solution where ultrasonic technology meets efficiency in a tank-to-tank cleaning system. Integrating ultrasonic cleaning as a pivotal step within a comprehensive cleaning process ensures unparalleled cleanliness. By seamlessly linking ultrasonic cleaning with rinsing, drying, and other processing steps in a unitized cleaning console, Aquarius™ guarantees process integrity and superior results.

This tank-to-tank system goes beyond basic cleaning, offering a complete solution with optional automated robotic transfer, environmental enclosure, and DI water systems. This integration enhances cleanliness levels, ensures process consistency, and significantly reduces labor requirements for parts cleaning. Engineered as pre-configured systems, Aquarius™ Series Multi-tank Ultrasonic Cleaning Systems address a wide range of parts cleaning needs.

Additionally, this adaptable platform can be customized to handle nitric or citric acid passivation requirements. Aquarius™ caters to diverse industry cleaning demands, with increased hoist load capacities, bio upgrades, and comprehensive data logging capabilities; Aquarius™ sets the standard for precision cleaning excellence.

Typical Applications:

- Electronics

- Optical

- Semiconductor

- Medical

- Aerospace

- Hard Disk Drive

- Final Cleaning

- Bio Upgrades

- Design Specs

- Optional Equipment

- Case Studies

- Videos

Design Specs

| Cleaning Sequence: | Wash & Dry (Wash, Rinse, Etch, Passivation, and Dry Stages Available) |

| Process Type: | Batch |

| Part Orientation: | Standard or Custom Processing Baskets |

| Production: | Low to High Volume |

| Max Work Envelope: | Up to 36″ Wide x 36″ Deep x 36″ High |

| Method of Loading / Unloading: | Manual or Automatic |

| Footprint: | Varies Depending on the Number of Stages |

| Cleaning Mechanisms: | Immersion / Ultrasonics / Spray / Turbulation / Rotation / Agitation |

| Drying Mechanisms: | High Volume, Heated Air with HEPA Filtration and or vacuum drying |

| Controls: | Programmable Controller & HMI Touch Screen or PC |

| Ultrasonic Frequency | 40kHz (3 or 7 frequency systems optional) |

Optional Equipment

- multiSONIK Multi-Frequency Ultrasonics-3 or 7 Frequency

- In-Tank Agitation

- Solution Sensors-Conductivity / PH / Specific Gravity

- Chemical Injection

- Cascading Rinse Tanks

- Environmental Enclosure

- HEPA Air Filtration

- Tank Ventilation System

- Auto Tank Lids

- Increased Hoist Load Capacities

- Data Logging

- multiSONIK Multi-Frequency Ultrasonics-3, or 7 Frequency

Bellows

Bellows Hip Implants

Hip Implants Spine Implants

Spine Implants Coated Glass Prisms

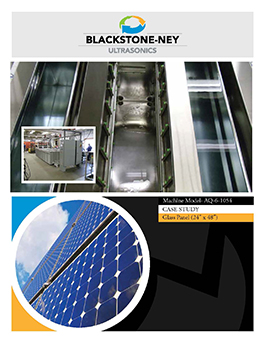

Coated Glass Prisms Solar Glass

Solar Glass Pots, Pans & Lids

Pots, Pans & Lids