Automotive Parts Cleaning

Blackstone-NEY develops a variety of ultrasonic cleaning solutions that are well suited to meet the challenges of automotive component cleaning. From heavy-duty vehicle parts to critical sensor assemblies, we have automotive parts cleaning needs covered. We design and deliver dependable equipment to help our customers meet ISO 16232 and VDA 19.1 driven technical cleanliness specifications.

Blackstone-Ney Ultrasonic Solutions

The Blackstone-NEY AgiSonic® ultrasonic cleaning system is designed to wash heavy-duty components, like automotive parts, with vertical parts agitation. This system is available in three standard sizes, each incorporating an air powered agitation platform that facilitates loading, unloading, and agitates parts with a 6″ stroke up to 15 times per minute.

The Blackstone-NEY Robosonic™ ultrasonic cleaning system is an automated tank to tank cleaning platform leveraging the use of 6-axis robotic handling to maximize throughput and provide footprint flexibility. Additionally, the use of the advanced robotic handling allows for functionality such as basket and part manipulation. This can assist in draining the parts or baskets between tanks, or avoiding air traps or splashing during part or basket placement.

A popular choice for tool rooms, racing shops, and remanufacturing businesses, GMC ultrasonic cleaning systems are available from stock in two standard sizes. The larger can accommodate parts with one dimension up to 35 inches and weighing up to 125 pounds. Both units are entirely self-contained, are supported on casters and operate from commonly available power supplies making them easy to move where needed.

The Aquarius Series of ultrasonic cleaning systems is another product group that offers advantages to the automotive industry, specifically for the production of electric cars. All ADAS (advanced driver assist systems) incorporate electronic sensor technologies. The assembly of these sensors must be done in a clean room to avoid having particulate obscure optical sensors and to avoid metal particles on PCBAs and other components. The die-cast and machined housings for these assemblies must be precision cleaned. Tier 1 and Tier 2 suppliers, such as PCBA manufacturers and die casting manufacturers will benefit from Lean Aquarius cleaning technologies for these sensitive components.

Applications:

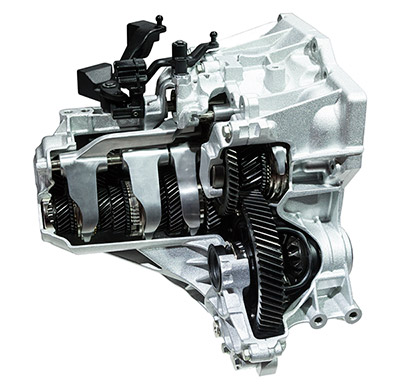

- Engine Heads & Blocks

- Differential Case

- Gearing

- Pre-Laser Welding

- Shafts

- Diesel Injectors

- Various Engine Components

- Torque Converters

- Input / Output Shafts

- Transmission Cases / Components

- Pinion Gears

- Brake Systems

- Steering

- A/C Systems

- Cylinder Heads

- Engine Dampener Components