It is with great sadness for us to share that John Fuchs has recently passed away. John has been associated with Blackstone NEY Ultrasonics for 52 years in many different roles. He is also well known in the industry as the creator of this blog on the Cleaning Technologies website that covers many subjects on … Continued

Valves and fittings are typically intricate and can be complex in design. They require precision cleaning to remove debris, oils, and other production materials. If valves and fittings are not thoroughly cleaned, their performance and reliability could be compromised in their intended applications.Blackstone-NEY Ultrasonics develops commercial precision ultrasonic cleaning

When it comes to evaluating particle residues remaining on parts after manufacturing, the “go to” is often particle counting. Particles remaining on parts after normal manufacturing operations are collected using a secondary, more aggressive washing method. Collected particles are then tallied by size, number and, in some cases, type and probable origin as a measure … Continued

In a very early blog written in 2011 I talked about the “Scotch” tape test for cleanliness. At that time I did not address quantification of the results other than as a visual assessment. In addition to evaluating general cleanliness, this technique is being found particularly applicable when determining the cleanliness of substrates that “shed” … Continued

I know, there I go with the titles agan – sorry. But it fits because I thought I’d start this series off with one of the simplest tests I know for cleanliness. It’s a good example of a test that, although effective, doesn’t cost a fortune and can give some pretty meaningful results. I’m not … Continued

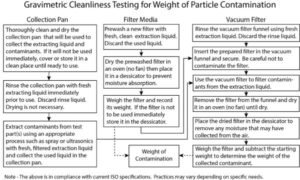

As I was writing the recent post about gravimetric Millipore testing it occurred to me that I was trying to boil a good-sized part of a 180+ page document into 500 or so words. It also occurred to me that many people don’t have the time for or interest in reading endless pages of specifications … Continued

“Millipore” testing evaluates cleanliness by extracting particulate contamination from a surface and then either weighing or counting and quantifying the collected particles to assess the cleanliness achieved by a prior cleaning means. The first step in either case is to collect and prepare for analysis any particulate residue remaining on the surface after pervious cleaning. … Continued

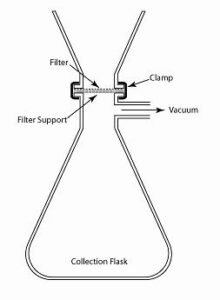

In preceding blogs we have talked about harvesting particles for evaluation and talked about specifications. Specifications may or may not dictate the harvesting process but almost always provide detail on how to evaluate the particles harvested in a process involving re-washing. The first step is to concentrate the harvested particles for evaluation. This usually involves a filtration and evaporation process. … Continued

Millipore testing is all about evaluating cleanliness based on the presence of particles or other solid, non-soluble contaminants. In general, it can not be used to detect the presence of hydrocarbons or other contaminants which will be solubilized in the extraction process. The results of Millipore testing are generally expressed by weight using gravimetric analysis … Continued

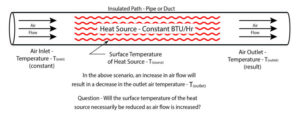

Once in a while a question comes up that I can’t think my way through. Here is one. Within an insulated system there is air passing over a heat source that constantly produces a certain number of BTU’s per hour. In the process, the air is heated from the inlet temperature to an elevated temperature … Continued