The surface tension of a liquid, as we have discussed earlier, is an important consideration in the selection of cleaning chemistry for a particular application but it also has relevance in several other ways as well. In earlier blogs, I have frequently referred to the importance of surface tension but haven’t really discussed what surface tension … Continued

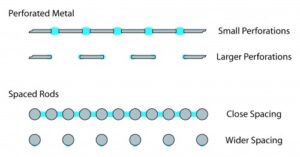

For all I have said about drying in the preceding blogs, maybe I should have started with this one. So here we go, better late than never. Although a seemingly “no brainer,” the idea of reducing the load on the dryer by eliminating as much water as possible prior to the drying process itself remains … Continued

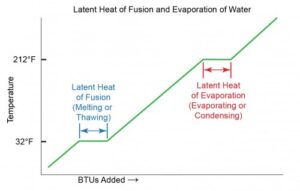

In reading the last couple of blogs it would be easy for the reader to come to the conclusion that the addition of heat is all that is needed to dry things. It would be nice and easy if that was the only consideration. The fact is that evaporative cooling is working against us in … Continued

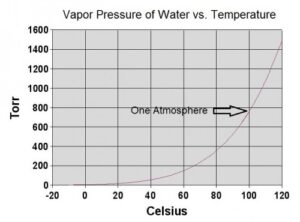

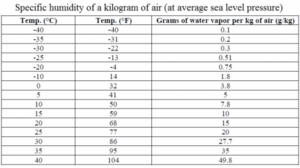

In the preceding blog, we learned that relative humidity of air is affected by temperature. Although I really didn’t say it, I’m sure readers have come to the conclusion that lower relative humidity will result in air which is “hungry” for water. Air that is at a low relative humidity, then, is beneficial to drying. … Continued

I first talked about drying a long time ago in the blog called “Don’t Forget Drying.” In that blog, I stressed the importance of drying as a part of the cleaning process. In some cases, changes in the cleaning process can affect drying but, for now, let’s just concentrate on drying. Drying simply means removing liquid … Continued

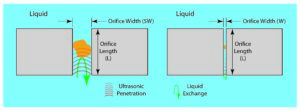

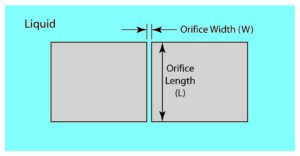

Dimensions of orifices and typical contaminant scenarios were discussed in preceding blogs. Today, let’s consider the role of ultrasonics in removing contaminants from orifices. First, we’ll consider the “classic” orifice consisting of a passageway through a solid. Then we’ll talk about some special cases which can have an impact on the ability of ultrasonics and … Continued

A few days ago, one of our customers asked one of our sales people what would seem like a very simple question. The question, in paraphrase, was – – “Do you know the relationship between ultrasonic frequency and the ability of ultrasonics to clean within a certain sized orifice.” Being a bit rushed when I received … Continued

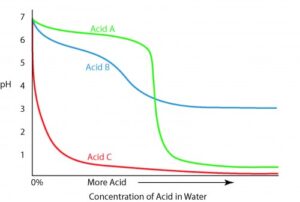

In a preceeding blog, I mentioned that pH is a logrhythmic function. As such, each increase of one pH unit represents a ten-fold change in the measured characteristic. This alone can lead to considerable confusion. But it gets worse! Concentration – One would think that pH would be directly related to concentration – – meaning … Continued

Titration is a procedure frequently used to measure the chemical concentration in a liquid. The concept is pretty simple. A specific volume of the solution under test is collected and put into a container which is usually an erlenmeyer flask or a beaker. The container can be glass, plastic or another material. Glass is often preferred because … Continued

In order to maintain process consistency in an industrial cleaning process, it is frequently necessary to monitor the concentration of chemistry in a cleaning solution. pH and specific gravity are two common parameters that can be used to determine the concentration of cleaning chemistries in water. This blog explores ways in which pH and specific gravity can … Continued