Automatic chemical addition and makeup is an attractive on feature on today’s sophisticated cleaning machines. Who wouldn’t appreciate eliminating the drudgery of taking samples, titrating, refractometer readings, or whatever and adding chemistry to a cleaning or rinsing bath manually? The trouble is that automatic chemical makeup is just not possible or applicable in all cases. Although there are … Continued

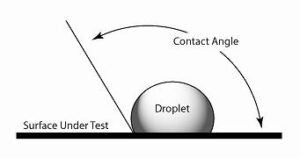

The tests described in the last couple of blogs are rudimentary ways to assess the surface activity of the surface being tested. In fact, they are all based on the concept of contact angle. A drop of water resting at equilibrium on a surface will intersect that surface at a measurable angle called the contact angle. The … Continued

In a recent blog, I touched on the fact that there is a limit to how long a cleaning solution will continue to produce clean parts as it becomes increasingly contaminated from use. Chemistry and disposing of spent chemistry are both expensive. Changing a bath usually results in a gap in production as the tank(s) … Continued

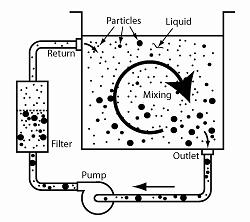

I admit, I stole that title from my grandma Bertha. But even in this day, the concept is applicable. Cleaning one thing is one thing, cleaning thousands of things is another. Let’s think about that. Cleaning, as we have discussed before, really amounts to moving contaminants from the surfaces being cleaned and sequestering them in another … Continued

When particles are the enemy, my general rule is filter, filter, filter! The cost of filtration is small compared to the overall benefit even if it is only “insurance.” There is, of course, the initial cost of installation (filter housings, pumps, plumbing, etc.) but the cost after that is going to be pretty much fixed provided … Continued

Blackstone-NEY Ultrasonics knows that there is no one solution to meet every ultrasonic cleaning need. In response, we now offer the widest range of ultrasonic cleaning process technology options available today using a single ultrasonic generator platform! Our totally new generator can be configured to provide the exact frequency, power and waveform to best meet … Continued

The Cleaning Technologies Group is a world class leader in providing passivation systems to the medical and aerospace industries. What exactly is passivation? Passivation is the removal of exogenous iron or iron compounds from the surface of stainless steel by means of chemical dissolution. A process extremely important to critical cleaning applications. Our systems combine … Continued

Blackstone-NEY Ultrasonics is pleased to announce its newly redesigned Aquarius tank to tank precision ultrasonic cleaning system. Our patented technology allows us to incorporate seven (7) independent frequencies, 40-80-120-140-170-220-270, in a single tank which makes for a very compact design. Complete with a fully automated robotic transfer this high production cleaning system is designed to … Continued

Ultrasonic cleaning is one step in a complete cleaning process. Combining ultrasonic cleaning with rinsing, drying and other processing steps in a unitized cleaning console helps assure process integrity. The addition of an automated, robotic transfer system provides process consistency and significantly reduces the labor required for parts cleaning. Aquarius™ Series Multi-tank Ultrasonic Cleaning Systems … Continued